| |||||||||||||||

Sharing the experience of planning, building and delivering a panelized home framing kit or package and the ups and downs of construction. Our goal is to answer questions and to help overcome all obstacles from financing to planning to obtaining the building permit and finally the delivery of your factory built pre-cut home framing kit to build your dream home. For more information please visit our website www.northcoastpackagedhomes.com.

Sunday, December 9, 2012

Holiday Building Crew

Monday, October 8, 2012

Building the Wall Panels

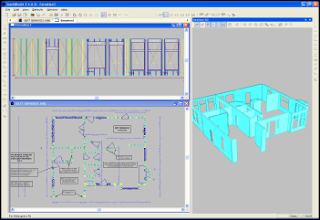

After the plans are completed either by us or your own architect and engineer the plans are converted into a three dimensional model. With custom plans errors are frequently found when the plans are quoted and more are discovered as the home is built by the computer. Answering questions at this stage of the building process is a large cost saving factor in using one of our home packages or kits.

The wall panels are then built in the factory, the shear sheathing nailed and the windows are installed.

The wall panels are then delivered to the job site.

A simple wall panel diagram is included showing where the individual panels are to be placed.

And the panels are lifted into place.

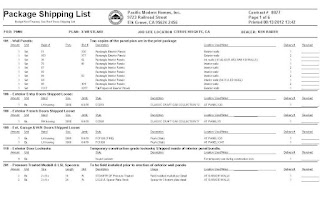

Along with the panel plan a computerized inventory also helps to identify the different parts of the home building kit and what they are used for.

For more information go to www.northcoastpackagedhomes.com

Thursday, September 20, 2012

DIY Building Kit

Although many clients at least consult with a framer or general contractor - it is not unusual for a client to participate, supervise or even do the basic assembly of the package. As our framing packages are conventional construction any qualified contractor or framer can easily assist as no special qualifications or experience are required.

Using this garage as a simple illustration, the wall panels are laid out in order and lifted into place:

Using this garage as a simple illustration, the wall panels are laid out in order and lifted into place:

For more information go to www.northcoastpackagedhomes.com

Monday, August 27, 2012

What is the difference between a stick-built, panelized, manufactured or modular home?

What is the difference?

Panelized, Packaged,

Pre-cut, Pre-fab or Kit Homes –These terms refer to a “stick built” home

constructed of factory-built wall panels with the windows installed and roof

trusses which are shipped to the site on trucks and lifted into place. When finished, a panelized home will be indistinguishable

from a “site-built” home but as any custom home they must comply with the local

building codes. But unlike a “site-built”

home construction time is greatly reduced and is less expensive to build.

Modular or “Off-frame”

Homes – These terms refer to a factory-built house constructed to the HUD

Code and the regulation of factories producing these homes is strict. Modular homes can be single- or

multi-sectional and are typically built on a 2 x 10 platform designed to be

placed over a crawl space. Modular homes

have completed finishes so the design choices are limited but this is a

comparatively quick and less expensive method of construction.

Manufactured or “On-frame”

Homes – These terms refer to a house built on a permanent chassis and

presently are not built to the HUD Code and do not meet the standards for

conventional financing. These homes are

completed in the factory and offer few design options but construction is quick

and they are the least expensive method of construction.

Deciding which type of home is better than the other

depends on the individual situation:

Transport - Since all but site-built homes are built to

be transported accessibility of the site is critical. As panelized homes are in smaller bundles

unloaded from a larger trailer they are deliverable to all but a few sites but no

special license is required as with a manufactured home.

Selling – A panelized home sells and

finances as any other custom stick built home.

The State’s manufactured housing board regulates and licenses persons

selling manufactured and modular homes. A real estate license is not required

to sell a panelized home package, modular or manufactured home not affixed to

real estate.

When planning on installing a manufactured or modular

home on a property, it may be necessary to see if there are any subdivision

covenants or zoning codes that may prevent the presence of a manufactured or

modular home on the property.

Additionally, when selling manufactured or modular homes this fact must

be disclosed. A serial number and label

is permanently attached to these homes showing compliance with building code

standards (modular) and HUD code (manufactured) or both.

Simply put a

panelized home package has all of the benefits of a custom site-built home providing higher quality at a lower cost.

It allows the home owner complete freedom in the design of the home and

choice of materials and it sells and finances and appreciates in value as a normal

house would. Although the quality of

modular and manufactured homes has increased tremendously, one should still

consider the long term value when constructing your dream home.

For more information go to www.northcoastpackagedhomes.com

For more information go to www.northcoastpackagedhomes.com

Friday, August 17, 2012

Nugent Art Studio Delivery (& Art!!)

Normally when I write about a delivery - it is because something interesting...........or difficult happened. This delivery was in the scope of moving a huge truck down a country road, well rather uneventful. We blocked traffic on the major road, backed down to the job site, did a little accidental tree trimming and then Clint threaded the trusses and longer pieces of lumber through the trees with the gradeall to the site. In other words pretty normal. The foundation and sub-floor were done and while the truck was being unloaded for the art studio, the contractor and crew started standing walls.

Sometimes though some sites are a lot of fun and I get to send photos back to the factory of the project under construction............

AZ

For more information go to www.northcoastpackagedhomes.com

Sometimes though some sites are a lot of fun and I get to send photos back to the factory of the project under construction............

Oops..............I meant the photo of the art studio.

Then some clients cannot resist surfing the lumber before we get the stickers fully underneath.

But all kidding aside - one of the great pleasures of my job is helping people with a new home or in this case a new art studio. And sometimes to share a little bit more about those clients. So when I said that I am helping with an artist's studio - I can share a little more. In addition to helping to create the labels for Imagery Winery and being a Professor of Art at a local university, I am very confident having seen his surfing skills to suggest he keep his day job!!

To see more images and learn more about Bob please click the link below:

AZ

For more information go to www.northcoastpackagedhomes.com

Monday, July 30, 2012

Client Recommendations

So many of my clients share the same goal in their construction projects - building a high quality, energy efficient, safe home economically. It is normally the research to achieve this goal that has them cross my path in the first place. And it is this quality that also has them finding new and/or innovative products that they use in the construction of their homes.

In order to share some of these products I am going to begin to put some of these referrals under "Useful Links." These products will be different than those referred to under "What's Included" which is specific products that are used in the manufacture of your framing package.

Needless to say I recommend that you do your own research on these products but the fact that one of my clients has already given a thumbs up hopefully gives your a head start!

In order to share some of these products I am going to begin to put some of these referrals under "Useful Links." These products will be different than those referred to under "What's Included" which is specific products that are used in the manufacture of your framing package.

Needless to say I recommend that you do your own research on these products but the fact that one of my clients has already given a thumbs up hopefully gives your a head start!

WUI approved flame and ember resistant vents - the only one with overlapping baffle protection.

With so many of my clients being in an area that the special Wildland Fire Codes applies to - this site was recommended as a high quality economical vent.

With so many of my clients being in an area that the special Wildland Fire Codes applies to - this site was recommended as a high quality economical vent.

Solar shingles - need I say more? Not inexpensive but an attractive alternative to getting off the grid.

For more information go to www.northcoastpackagedhomes.com

Monday, June 25, 2012

Universal Design

What is Universal Design?

Universal Design is the incorporation of structural and non-structural elements into a residence that are attractive and usable by all persons regardless of age, size and ability. A home designed using these principles simplifies daily life for residents and guests as needs and physical abilities change. Incorporating Universal Design features into a residence in the pre-construction stage adds little cost relative to the future cost of retrofitting a residence built with traditional design features. Done well, Universal design becomes a virtually invisible element that benefits any person occupying or utilizing a residence.Objective - Insure accessibility to the residence for any person including those with different physical abilities.

- Provide an accessible route of travel from the public sidewalk or street to the primary entrance in the form of a graded path, ramp or driveway to graded path.

- Provide at least one step free entrance into the home.

- Provide a 60' x 60' (5' diameter) clearance at the primary entrance to the home

Objective - Improve overall circulation and allow people, furniture and appliances to move with ease in and out of the home.

- Provide flush thresholds exterior maximum of 1/2 inch beveled, interior maximum 1/4 inch

- Provide 42" wide hallways with 32" clearance doorways on an accessible route

Objective - Reduce bending, straining and twisting when turning on lights, faucets or when reaching for items on shelves.

- Include variable height (28" - 42") work surfaces such as counter tops, sinks and/or cook tops in the kitchen

- 50% of all storage within the home should be less than 54' high

- Provide structural reinforcement within bathroom walls adjacent to toilet, shower and bathtub for future installation of grab bars

- Full bathroom on an accessible route including a minimum 60' x 60' turning area, walk in shower and a clear space for use of the sink

- Include adjustable (36" - 60") rods and shelves within closets

- Install lever style door handles and faucet handles and rocker panel light switches throughout the home

- Install electrical panel with top more than 54" above floor and include a minimum 30" x 48" clear floor space in front of panel

- Install light switches 42" - 48" above the floor, electrical outlets 18" - 24" above the floor and thermostats no more than 48" above the floor.

Objective - Create easy recognition of the junction of floor surfaces and walls to reduce the likelihood of injury.

- Include color contrasts between the following areas: floor surfaces and trims, stair treads and risers, and counter tops and front edges or cabinet faces

- Provide smooth, slip resistant flooring. if carpeted use low density (less than 1/2 inch high pile) with a firm pad

Objective - Allow residents and visitors complete access to home when changing needs or physical abilities occur.

- Complete single floor living spaces. Provide entry, kitchen, laundry area, full bath and flex room on primary level of home

- Flex room should be usable as family room, nursery, playroom, home office or bedroom depending on the needs of the residents

- Avoid steps between rooms or areas on the primary floor of the residence

Friday, June 15, 2012

The Difference Between Stick Built and Panelization

To your local building department or your lender, there is no difference between a panelized home and a conventional on site stick built home.

To you the owner, the differences are tremendous.

Higher Quality - Your custom framing package will be factory built with all of the wall panels constructed from dry lumber on a gig so that every corner is 90 degrees. This results in a better product than can be built on the ground on the site.

Speed of Construction - This photograph was taken 48 hours after the delivery of the framing package. The framing of a typical home is done in days rather than months.

Guaranteed Materials - You are guaranteed the materials required to assemble your framing package are delivered to your site. Years of experience insures that all of the materials are shipped with the wall panels and roof trusses to insure assembly. This saves multiple trips to the store to purchase additional materials.

Local Representation - From advice on land purchase and choosing of the design through the delivery and assembly of your framing package we are there to assist you. Rain or shine.

For more information go to www.northcoastpackagedhomes.com

To you the owner, the differences are tremendous.

Higher Quality - Your custom framing package will be factory built with all of the wall panels constructed from dry lumber on a gig so that every corner is 90 degrees. This results in a better product than can be built on the ground on the site.

Cost Savings - Typically your framing package will be 10 to 25% less on site framing depending on the location and design.

Pre-Engineered Home Plans - We offer 36 home plans that can be modified to meet your site, needs and local building department requirements. Fully engineered these drawings are ready to submit for your permit to California standards and the all code corrections are done at no additional charge. With the current 100% rebate on these plans this can be a savings of many thousands of dollars.

Custom Drafting and Engineering - If one of the Pre-Engineered plans does not meet your needs we can assist you will custom drafting and engineering. Completing hundreds of construction documents each year we not only offer engineering solutions that can save money but also a very high quality product. It is not unusual for our drawings to go through plan check without a single redline correction. And documents that our prepared by us receive an additional discount built into the package pricing.

Guaranteed Pricing - Depending on the size of the deposit given pricing can be guaranteed up to six months from the time of the contract to the date of delivery. This is unparalleled in an industry where price increases occur on a regular basis and bids are only good for 30 days.

Speed of Construction - This photograph was taken 48 hours after the delivery of the framing package. The framing of a typical home is done in days rather than months.

Guaranteed Materials - You are guaranteed the materials required to assemble your framing package are delivered to your site. Years of experience insures that all of the materials are shipped with the wall panels and roof trusses to insure assembly. This saves multiple trips to the store to purchase additional materials.

Local Representation - From advice on land purchase and choosing of the design through the delivery and assembly of your framing package we are there to assist you. Rain or shine.

For more information go to www.northcoastpackagedhomes.com

Friday, May 18, 2012

Very Busy Spring

Well spring is fully upon us and we have been very busy helping clients get new projects begun, drawn and through their local building departments.

The residence up in Angwin is almost done and I did have a chance to get up there about a month ago and here are some afternoon pictures (which are unfortunately a little dark!)

The residence up in Angwin is almost done and I did have a chance to get up there about a month ago and here are some afternoon pictures (which are unfortunately a little dark!)

For more information go to www.northcoastpackagedhomes.com

Sunday, April 22, 2012

A True Story

True story - the client on this house saw one of our Craigslist ads and showed her Dad the website - and it turned out he had built his house decades before with a package from Pacific Modern Homes. I had the chance to visit after the house was completed and Whitney gave me a disc with almost 200 photos and here are just a few!

|

| Unloading wall panels at the building site |

|

| Sub-framed next to garage started |

|

| Garage framing |

|

| Raising a pre-engineered wall panel |

|

| The window is protected during transport and panel installation |

|

| Pre-cut wall almost in place |

|

| A final adjustment of the wall panel |

|

| The interior framed walls |

|

| The engineered roof trusses lifted by a crane (or can be done by a gradeall or by hand) For more information go to www.northcoastpackagedhomes.com |

Thursday, April 5, 2012

Guaranteed Packaged Home Pricing

Unlike a typical contractor we are in a position to offer a price guarantee for longer than the conventional 30 days due to our buying power and ability to store materials.

Once the quote is generated and the contract for the package is signed the price is guaranteed until the end of the month that the original contract is signed. The price guarantee is then extended with deposit increases as follows:

15% Deposit 2 months to deliver

30% Deposit 3 months to deliver

45% Deposit 4 months to deliver

70% Deposit 5 months to deliver

100% Deposit 6 months to deliver

The deposit must include the tax and freight and the delivery must occur within the proscribed time period. If the delivery date is not extended the price is subject to being raised if the overall prices have increased. For example, prices have not been raised in the last year but we are anticipating a slight increase in the next few months due to increases in prices from suppliers. If a contract was signed today and a 100% deposit was made the contract would not change for 6 months if delivered within that time period. If prices go up during that time period, the package price is guaranteed to not change.

This price guarantee is offered to all of our clients.

For more information go to www.northcoastpackagedhomes.com

Once the quote is generated and the contract for the package is signed the price is guaranteed until the end of the month that the original contract is signed. The price guarantee is then extended with deposit increases as follows:

15% Deposit 2 months to deliver

30% Deposit 3 months to deliver

45% Deposit 4 months to deliver

70% Deposit 5 months to deliver

100% Deposit 6 months to deliver

The deposit must include the tax and freight and the delivery must occur within the proscribed time period. If the delivery date is not extended the price is subject to being raised if the overall prices have increased. For example, prices have not been raised in the last year but we are anticipating a slight increase in the next few months due to increases in prices from suppliers. If a contract was signed today and a 100% deposit was made the contract would not change for 6 months if delivered within that time period. If prices go up during that time period, the package price is guaranteed to not change.

This price guarantee is offered to all of our clients.

For more information go to www.northcoastpackagedhomes.com

Panelized Home Package Pricing

Next to answering the question of what is a panelized or packaged home, the next most frequently asked question is 'how much does it cost?' And how is the price generated?

Our new home in Angwin is

progressing. Our general contractor expects us to move in late June or

early July. We hope so. I told you months ago that using Pacific

Modern Homes to do the framing off site (Elk Grove, CA) saved us a substantial

amount of money on the project. The savings were so substantial, it

allowed us to go forward with the project this year. (G.S. Napa County)

As with everything else the pricing of a panelized kit is relative to the size and the complexity of the design. The packages that we have sold have ranged from $10 a square foot for a simple garage to $40 a square foot for a complex home with a lot of windows and everything in between. Our package pricing is done with a sophisticated program that measures the quantity and engineering of materials and then factors in the plans and the complexity of the design.

The simplest design is a rectangle with a straight gable roof. After that our pricing program factors in such things as the number of corners,the number of stories, the number of roof trusses including shape and span (so a hip roof has many more truss types than a straight gable) and then individual elements such as a bay window.

Another element that is a given percentage which is factored into the program is the origin of the plans. One of our standard pre-engineered plans is the least costly, followed by a modified standard plan then a custom plan drawn by PMHI and finally by a custom plan drawn by your own architect and engineer. Although many custom plans are cleanly and thoroughly drawn, frequently they are not. The factor applied is based on 40+ years of experience and they have factored in an average.

Finally one thing which we cannot do with this program is what we call 'boutique pricing'. With the standard plans we have assigned dollar amounts to some standard options such as 2 x 6 exterior wall, changing the exterior material or adding grids to the windows. And with other changes we can give you a rough estimate. But the program does not itemize and the program is run once. This is done as a benefit to all as doing a quote or a bid is a very time consuming job. In order to provide 'boutique pricing' we would have to raise prices which would defeat the purpose of attempting to save money.

With this said we are happy to give you a very good estimate of your package price with the tax and delivery included even before the drawings are fully engineered.

For more information go to www.northcoastpackagedhomes.com

For more information go to www.northcoastpackagedhomes.com

Wednesday, April 4, 2012

Finding Land for a Panelized Home

Finding the correct lot or piece of land is one of the first and most exciting steps in the building process. We recommend that you work with a real estate agent who is well versed in your local area, bare land sales and your local building department regulations. It is also advisable for your agent to provide you with a Comparative Market Analysis of the home you are trying to build in your neighborhood. Then the simple formula that is recommended to use is:

Land + Cost of Construction < Resale Value of the House

The tricky part of this is the cost of construction. We can help you with the costs of the actual construction of the house but there are many other costs associated with construction that your real estate agent should guide you through during your "inspection" or "due diligence" period. These should minimally include:

- The cost of septic and well or sewer and water. In some areas it is wise to ask if there is a water moratorium.

- The cost of electricity and any other services needed such as cable.

- Permit costs including school fees, low income housing fees, any other fees required by your building department.

- The cost of accessing the property which can include not only the drive but the type of material and any other special requirements such as perhaps a culvert or paving a steep section.

- Any special soil concerns and any anticipated circumstances with the foundation. It is impossible to predict all contingencies such as hitting a large rock but the building department should be able to tell you if you are going to need a geologist's report. Some phone calls to determine the cost of the report and any anticipated problems would be prudent.

- All departments of the building and planning departments should be queried as to any special requirements such as an unusual snow load, seismic zone, FEMA or coastal commission approval. They should also be able to tell you if you are in any protected wetland areas or areas that might be affected by such things as Native American artifacts.

- Any architectural review or CC&Rs that can affect the development of the property.

- Any other issues with the property such as easements or other rights.

Although many of these items will not apply to most properties - on occasion one or more may be a very large expense. We had one client who thought that the lot they were purchasing was an excellent deal until they learned that it was going to take a $100,000 bridge to access the property. This is the additional kind of cost which is difficult to capture in the comparison to other similar houses.

If some extraordinary construction cost is discovered during the inspection phase it gives you as the buyer the opportunity to re-negotiate the price with the seller so that the formula works.

And please do not hesitate to call if you have any questions.

For more information go to www.northcoastpackagedhomes.com

For more information go to www.northcoastpackagedhomes.com

Friday, March 30, 2012

Building on a Sloped Site

One of the most common questions asked is "Can I put one of your panelized homes on a sloped site?"

First, I must clarify that each of our home packages is designed and built custom to you and your site's needs. For a sloped site we can either help you design a completely custom design or we can modify one of our standard pre-engineered packaged homes.

First, I must clarify that each of our home packages is designed and built custom to you and your site's needs. For a sloped site we can either help you design a completely custom design or we can modify one of our standard pre-engineered packaged homes.

The custom home in West Sonoma County was designed with the help of North Coast Packaged Homes and was built to take advantage of the down sloped site and the incredible views to the south. The large covered porch was designed to protect the great room from direct summer sun.

This Napa model was also built on a steep down slope lot. The driveway gently sloped down to the garage so that the garage and the front of the house appear at grade. The rear of the house is elevated allowing for a large storage area under one portion of the house and a raised deck facing the view.

This modified New Haven was built on an up slope site. The slope was adjusted with the use of retaining walls incorporated into the landscape and by slightly dropping the garage. Usually correctly orienting the home and the driveway is the first step allowing easy access for automobiles.

A more extreme example of a steep up slope lot was in Lake County. In this modification the hillside was so steep we designed the garage to go underneath the house and made the garage in the plan into a large family/game room.

As you can see by these examples we can design the foundation to fit your site and we can always adapt the pre-cut home kits to fit on that foundation.

For more information go to www.northcoastpackagedhomes.com

Monday, March 26, 2012

Closed in and the Finishing Begins

Within two weeks all of the sheathing is complete and the rough plumbing is started.

Two more weeks and the roofing is complete and the house wrap applied.

And a month later the exterior siding is applied and the plumbing and electrical are complete.

Three and a half months after the delivery the house is complete and the furniture moved in.

For more information go to www.northcoastpackagedhomes.com

Subscribe to:

Posts (Atom)

.jpg)